June 2025

Or, things will look worse before they look better.

Green Man Knives is now in limbo. Somehow, we moved all the existing equipment and tools out of the old workshop and surroundings. Workbenches, lathe, belt-grinder, pillar drill, forge, anvil… plus all the stuff on shelves, in drawers and in boxes. All now sits under tarps and awnings elsewhere in the garden. Mounds are piled head-high in the garden room, and we brace ourselves to live in chaos until the works are complete.

A small sample of workshop contents

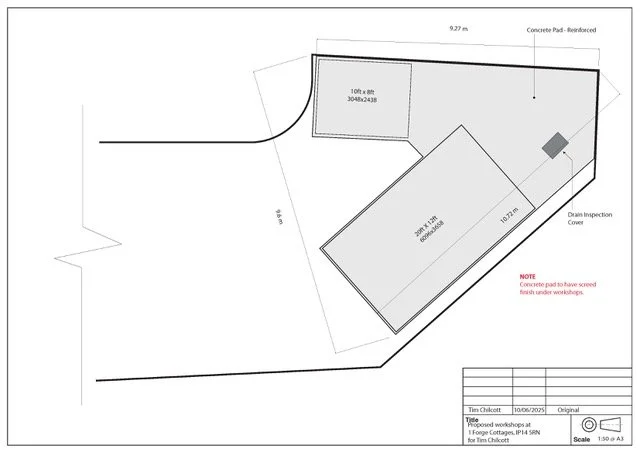

Next, the demolition of the old workshop, levelling of the site, and creation of concrete bases. Not only is the space an extremely awkward shape, but our garden also has no vehicle access. We are very lucky to look out onto a field at the back, but we’re mid-terrace, down a country track, and the only access is via narrow footpaths round the neighbouring houses, or through the house itself.

After much negotiation, the landowner agreed for field access via his farm… but only for a limited time, as the field was earmarked for new usage. Permission granted, Tim cut down trees and removed the fence on the boundary. But then we had to find a groundworks company whose contractors were happy to bring their vehicles and equipment through a farm and over a field.

But now the old building has gone, flattened like so much matchwood. The strangely sunken area where it stood was filled with hardcore. The guys uprooted old hedge stumps, scraped off a large weed-covered gravel area, and built up a drain inspection hole to the right level. Then they took several days to create the weirdly shaped reinforced concrete base.

Farewell, old shed

Main workshop bases done

So the workshop will be up and running soon, right? Well, no. Tim has been frustrated by some companies who can’t make anything that doesn’t fit within their rigid interpretation of ‘a workshop’. They can’t produce one without a wooden floor… they can’t read a carefully drawn building plan… they don’t know what a ‘stable door’ is, and when he tells them, they can’t provide one. The upshot is that it was quite a while before a suitable company was found, and of course, there’s a waiting list. So it’ll be October before we get delivery of the buildings themselves, and in the meantime, Tim can’t make knives. What on earth will he find to do? 😉